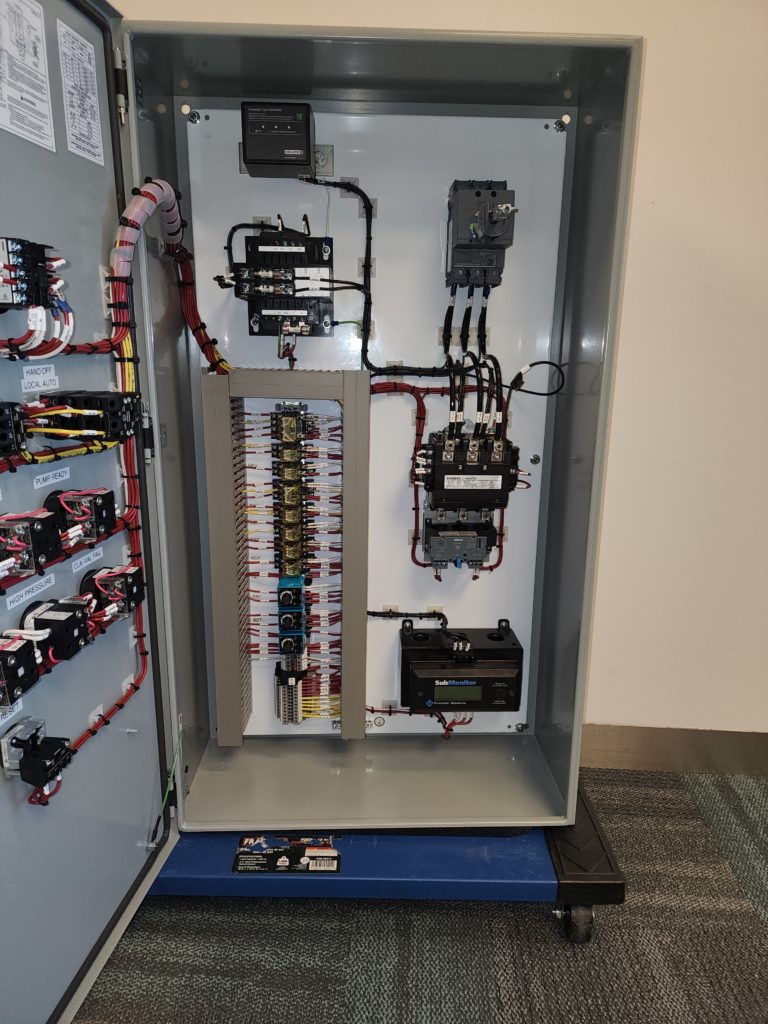

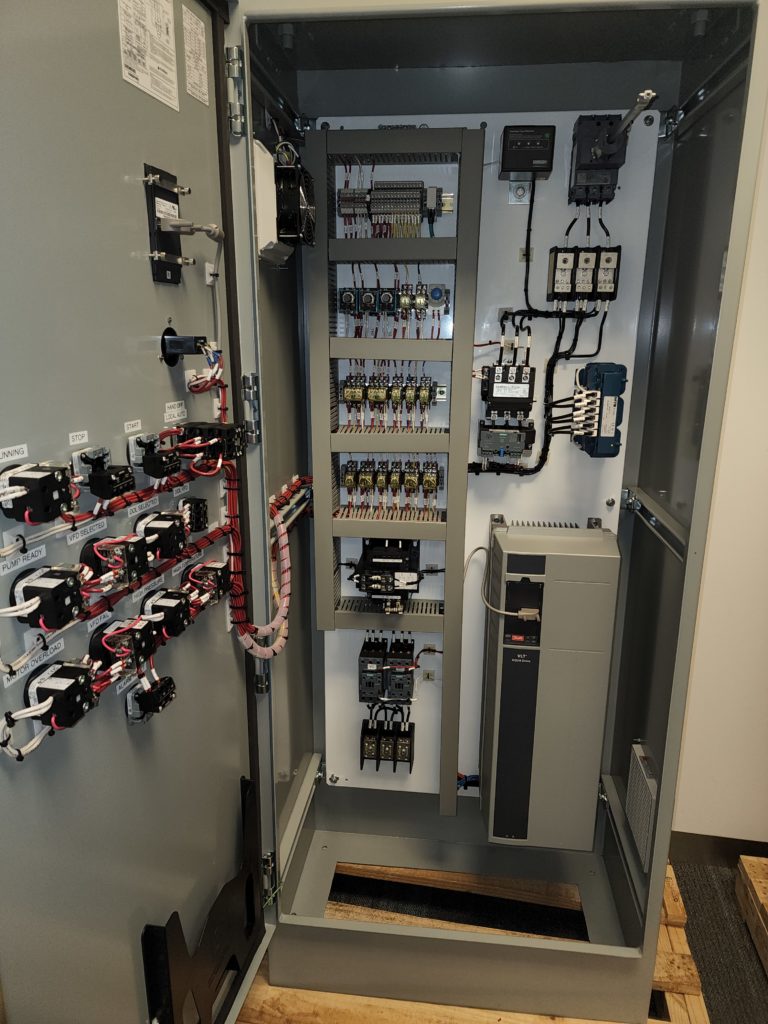

Control panels built PLC cabinets for the Booster Pump 1-3 starters, the BW starter, the A/C starter, the well pump starter, an Arsenic Treatment OIT Cabinet, the well 3 hydro tank compressor, and a dual sump control panel. They also did the programming for Well 3 and the Booster pump 1-3 controls and associated alarms, the storage tank control and associated alarms, the arsenic treatment system flow monitoring and associated alarms, the backwash tank sump control and associated alarms, the OIT programming per P&ID. Set up the VFD, network switch, instrumentation, radio modem, provided data tag list for SCADA, startup services, and operator training.